BUILDING WITH SIPS AND SCREW PILES

IT’S JUST BETTER

-

SUPERIOR INSULATION

SIPs provide superior thermal insulation due to the combination of a rigid foam core (typically expanded polystyrene or polyurethane) sandwiched between two structural panels. This helps prevent heat loss from the foundation, improving energy efficiency and reducing heating costs.

-

SUPERIOR STENGTH

SIPs are known for their strength-to-weight ratio. When designed for below-grade applications, SIPs can provide structural stability, resisting both vertical and lateral loads. This strength can reduce the need for additional reinforcement in foundation walls.

-

SUPERIOR SPEED

SIPs are pre-manufactured in large panels, which can significantly speed up the construction process this can reduce the time and labor needed to install foundation walls compared to traditional concrete or masonry foundations.

APEX SIPS PRODUCED IN TULSA OKLAHOMA

Structural Insulated Panels (SIPs) are primarily used for above-grade construction, but they offer several benefits when used below grade, such as in basements or foundation walls. Below are some advantages of using SIPs in below-grade applications:

1. Excellent Insulation

SIPs provide superior thermal insulation due to the combination of a rigid foam core (typically expanded polystyrene or polyurethane) sandwiched between two structural panels. This helps prevent heat loss from the foundation, improving energy efficiency and reducing heating costs.

2. Moisture Resistance (When Properly Treated)

SIPs can be designed and treated with moisture-resistant coatings or barriers, reducing the risk of moisture penetration and associated problems such as mold, mildew, or rot. This can be especially important in below-grade applications where water intrusion is more common.

3. Speed of Installation

SIPs are pre-manufactured in large panels, which can significantly speed up the construction process. Below-grade, this can reduce the time and labor needed to install foundation walls compared to traditional concrete or masonry foundations.

4. Structural Strength

SIPs are known for their strength-to-weight ratio. When designed for below-grade applications, SIPs can provide structural stability, resisting both vertical and lateral loads. This strength can reduce the need for additional reinforcement in foundation walls.

5. Environmental Benefits

SIPs are often made from environmentally friendly materials, and their energy-efficient nature means less energy is needed to heat or cool the building. Over time, this can lead to a smaller carbon footprint for the structure.

6. Reduced Thermal Bridging

Traditional concrete foundations often have thermal bridging issues, where heat is lost through the structural members. SIPs, by contrast, provide continuous insulation, minimizing these thermal bridges and improving overall energy efficiency.

7. Design Flexibility

SIPs can be customized and manufactured to fit a wide range of designs and configurations. This flexibility can make them an attractive option for below-grade structures that require unique shapes or layouts.

8. Less Dependence on Concrete

Using SIPs below grade can reduce the amount of concrete required for a project, potentially lowering costs and carbon emissions. This is especially relevant when considering the environmental impact of cement production.

Considerations:

Waterproofing: Special care must be taken with waterproofing SIPs below grade since they are more susceptible to water damage than traditional concrete or masonry. Proper drainage systems, waterproof membranes, and coatings are essential.

Durability: SIPs may require additional protection from the elements (like backfill pressure and moisture) in below-grade applications. This often involves using treated materials or protective coatings.

Cost: While SIPs offer many benefits, the cost of using them below grade can sometimes be higher compared to traditional methods, especially if additional waterproofing or protective measures are necessary.

In conclusion, SIPs offer excellent insulation, speed, and environmental benefits for below-grade applications, but require careful planning around moisture protection and durability to perform effectively in those conditions.

AMERICAN STRONGHOLD

/

EARTH ANCHORS

AMERICAN STRONGHOLD / EARTH ANCHORS

AMERICAN STRONGHOLD: EARTH ANCHORS and HELICAL PILES

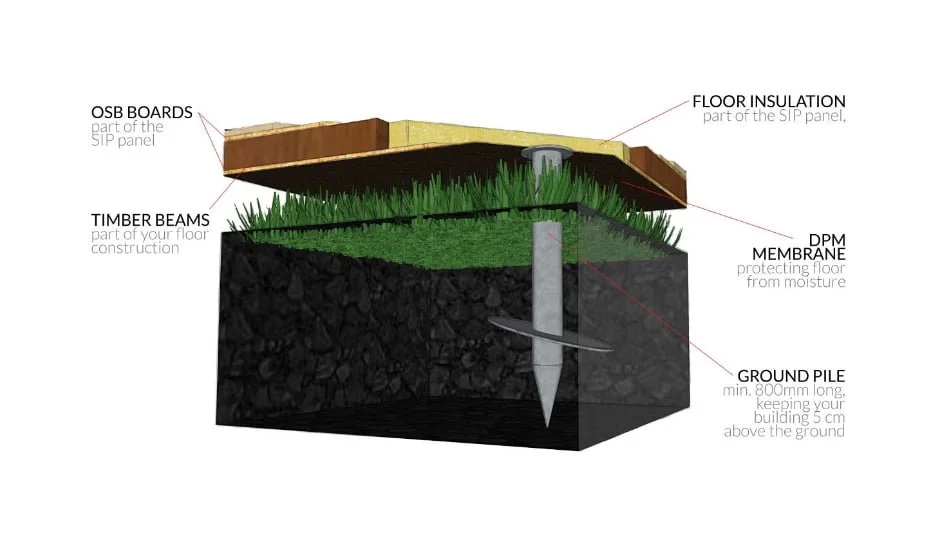

Helical Pile Foundations are deep foundation systems that use screw-like steel shafts to anchor structures into the ground. Each helical pile consists of a steel shaft with one or more helical plates (helix) welded to it. These piles are installed by rotating them into the ground, much like a screw, until they reach load-bearing soil or bedrock. Once installed, they provide vertical and lateral support for structures.

Key Advantages of Helical Pile Foundations Over Monolithic Slab Foundations:

Versatility in Soil Conditions:

Helical piles are effective in a wide variety of soil types, from loose sand to clay, making them suitable for areas with challenging soil conditions.

In contrast, monolithic slab foundations (which are poured as a single concrete structure directly on the ground) depend on uniform soil conditions to maintain integrity. Any soil movement, like settling or heaving, can crack and damage the slab.

Minimal Excavation:

Helical piles require minimal site disturbance since they are screwed directly into the ground with little to no excavation.

Monolithic slabs, on the other hand, involve significant site preparation, grading, and excavation, especially for larger buildings.

Ease of Installation:

Helical piles can be installed quickly, with minimal heavy equipment, and can even be installed in tight or confined spaces. This can be a huge advantage in areas with limited access.

A monolithic slab requires a carefully prepared site, significant manpower, and curing time for the concrete to achieve structural strength.

Adaptability to Changing Loads:

Helical piles can be adjusted during installation to account for changes in load requirements. If the structure needs reinforcement or if the load increases (due to an extension, for example), additional piles can be installed or existing piles can be re-torqued.

Monolithic slabs are static; if the load increases beyond the slab's capacity, it can lead to failure, and strengthening the slab post-construction is much more complicated and costly.

Resistance to Environmental Changes:

Helical piles are less affected by freeze-thaw cycles, expansive soils, and water table fluctuations. Since they anchor deep into the stable layers of soil, they maintain the structure’s integrity despite surface conditions.

Monolithic slabs, sitting closer to the surface, are more vulnerable to these environmental changes, potentially leading to cracks and shifting over time.

Reduced Environmental Impact:

Since they require less excavation and site preparation, helical piles have a smaller environmental footprint. They are also reusable and can be removed or reinstalled with ease, making them more sustainable.

Monolithic slabs are permanent and involve the use of large amounts of concrete, which has a high carbon footprint in production.

Cost-Effectiveness:

In challenging soil conditions, the cost of preparing the site and ensuring stability for a monolithic slab can escalate. Helical piles can be more cost-effective in these scenarios due to easier and faster installation.

For ideal soil conditions, monolithic slabs may sometimes be cheaper, but the potential for long-term maintenance due to cracking or soil movement can offset those initial savings.

Use Cases:

Helical Piles: Used in areas with poor soil conditions, on steep slopes, or in flood zones. They’re common in both residential and commercial projects, especially for retrofitting and repairs.

Monolithic Slab: Often used for residential homes or small commercial buildings in areas with stable, well-draining soils.

In summary, helical pile foundations offer greater adaptability, stability, and resilience in varied soil conditions and challenging environments, while monolithic slab foundations are more straightforward but less flexible and more dependent on stable site conditions.

SIPS BELOW GRADE

Here are five good reasons why using below-grade SIPs makes sense:

There is no waiting for concrete to cure

SIP basement/foundation walls won't crack

You can use the same carpenters for above and below grade walls

No additional inside framing or insulating to do on the exterior shell

You'll be left with a warm, dry basement that is easier to finish, and living spaces that will have the same feel of above-grade rooms